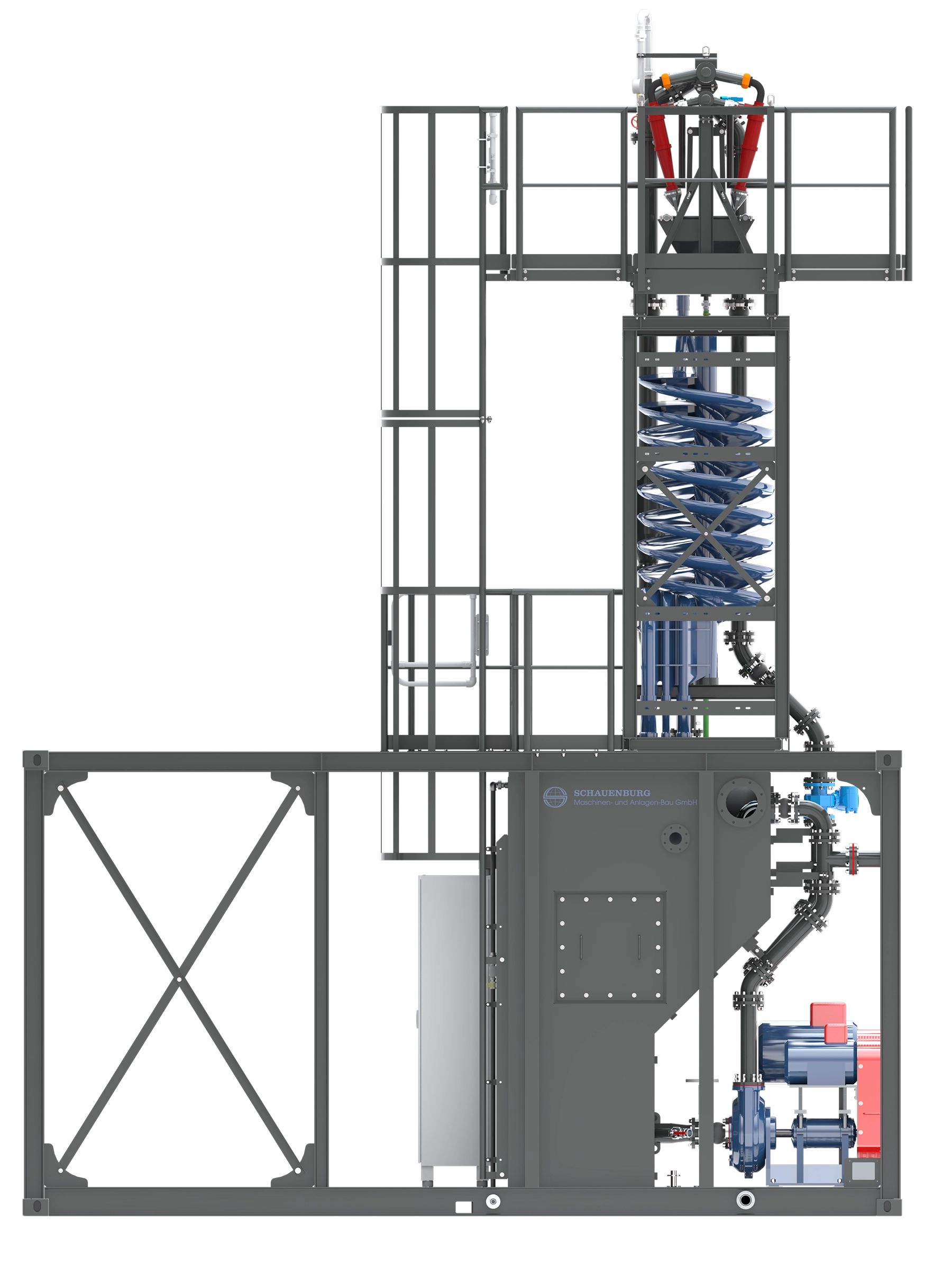

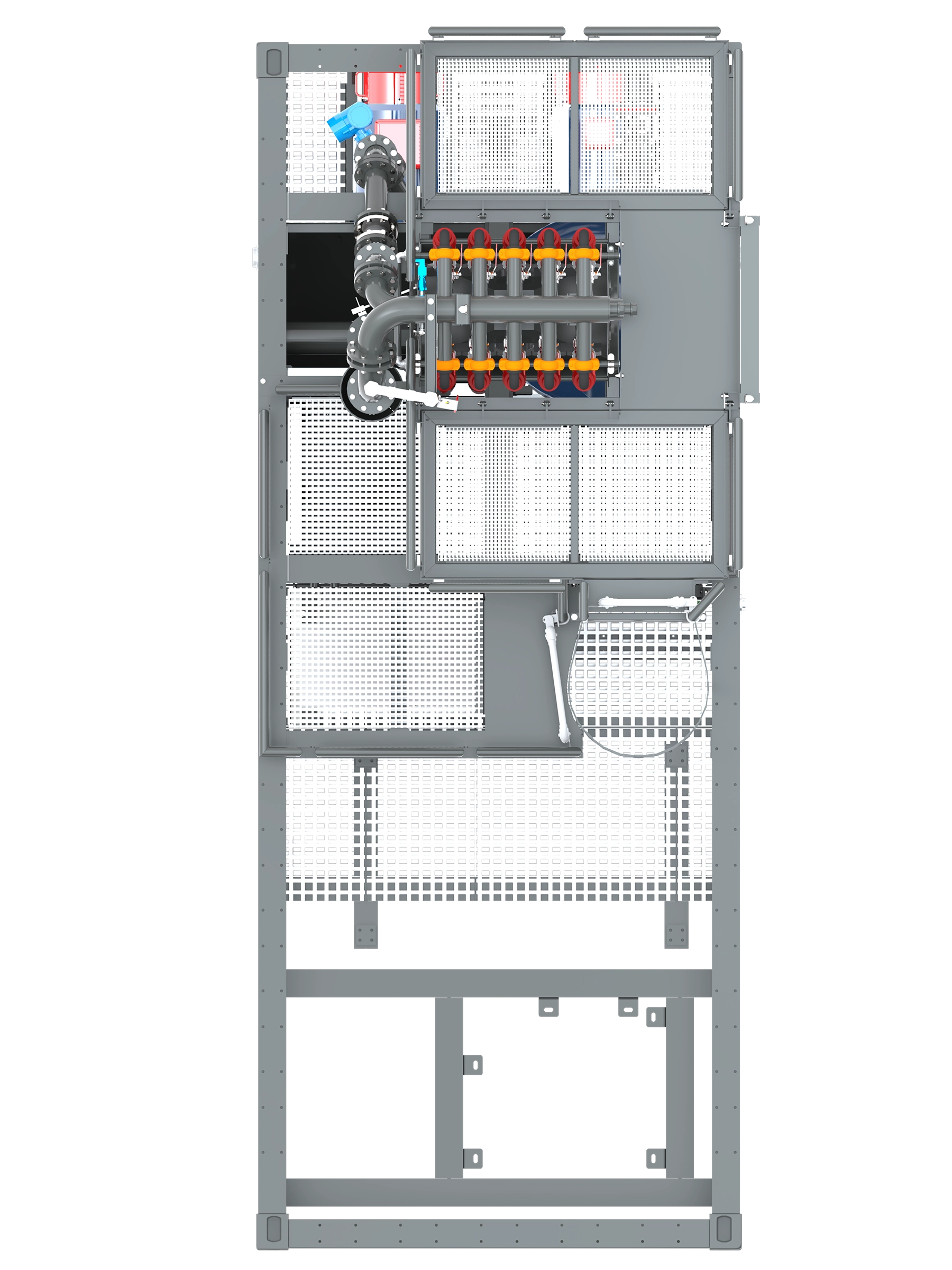

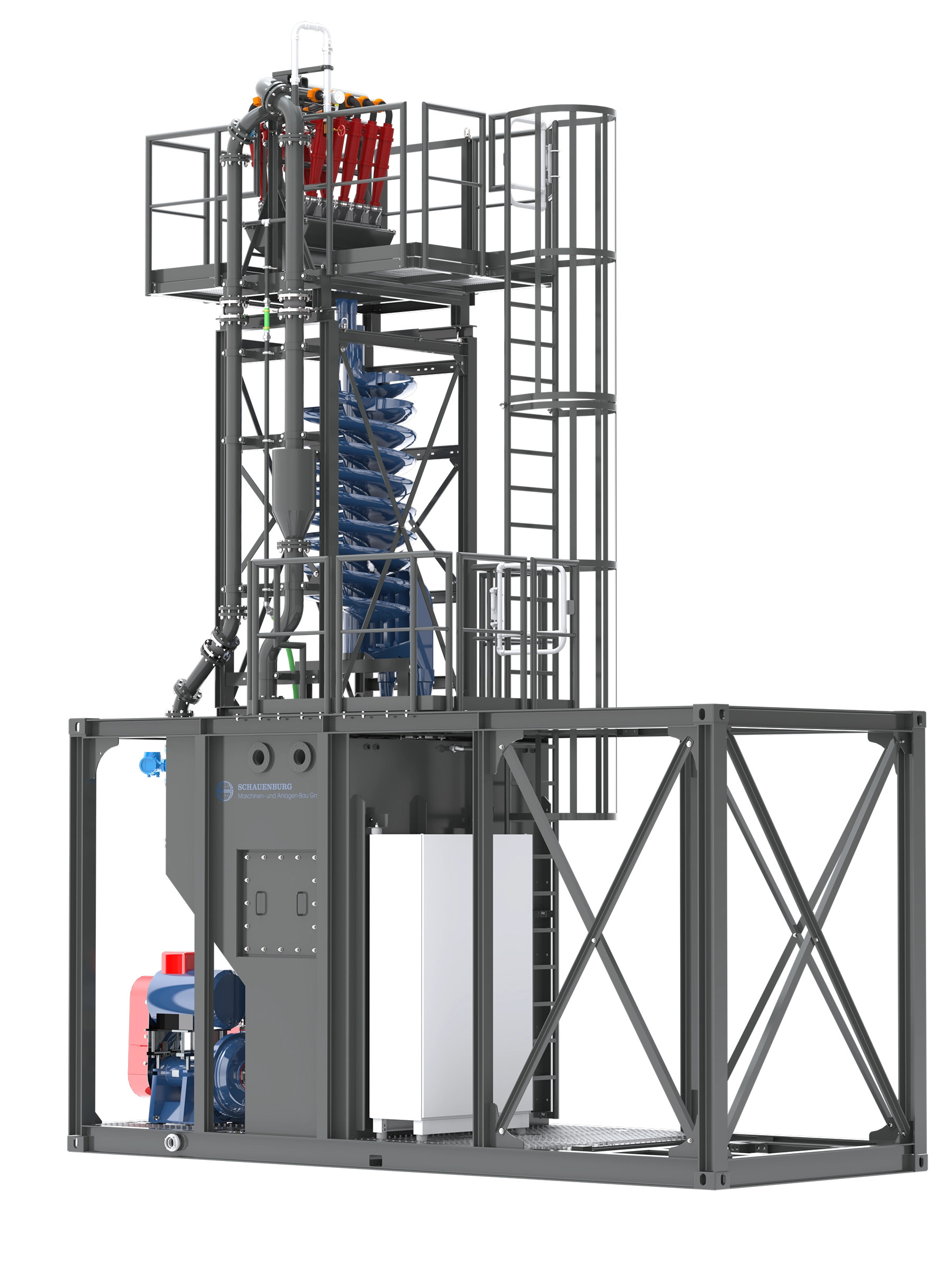

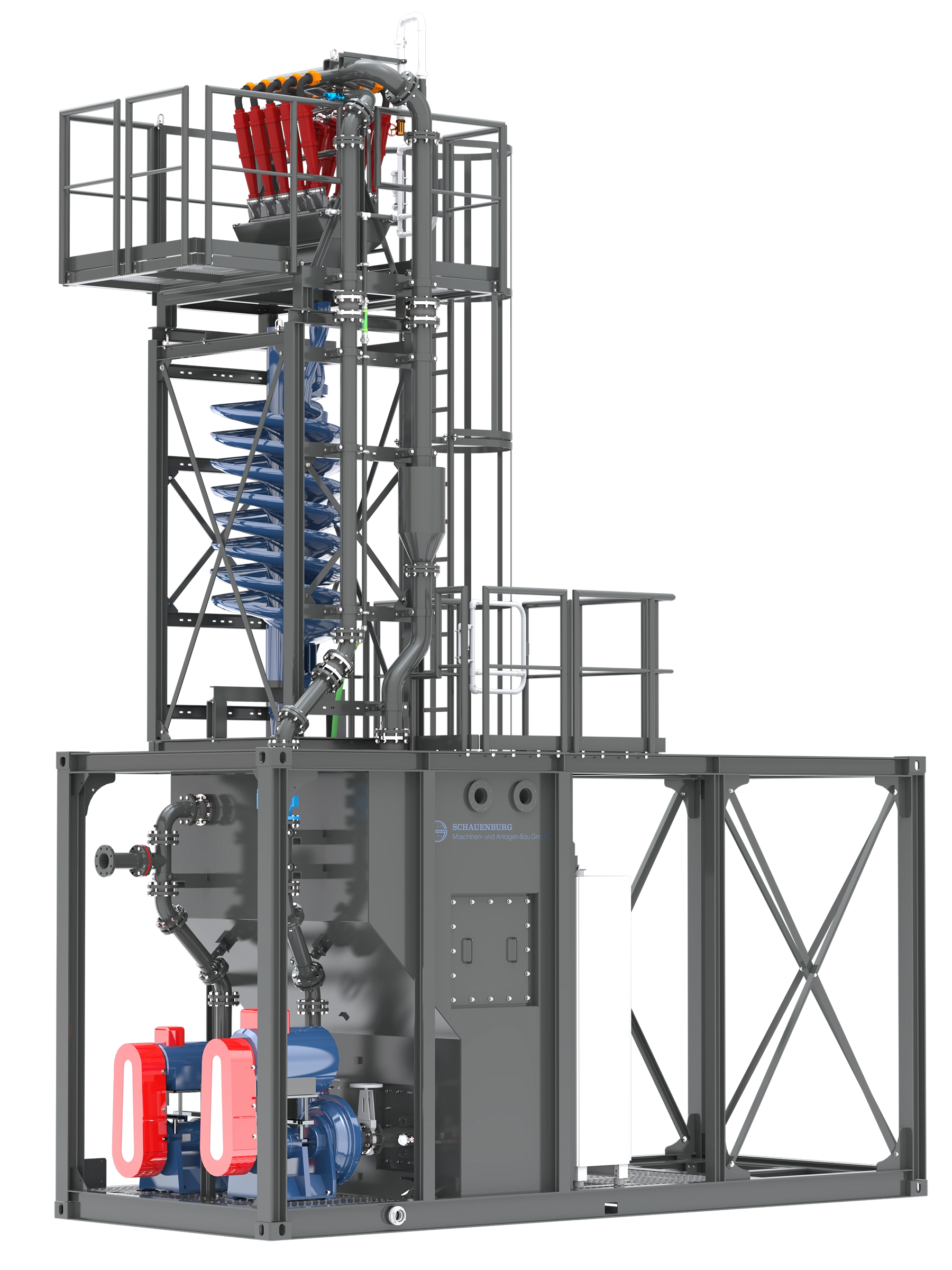

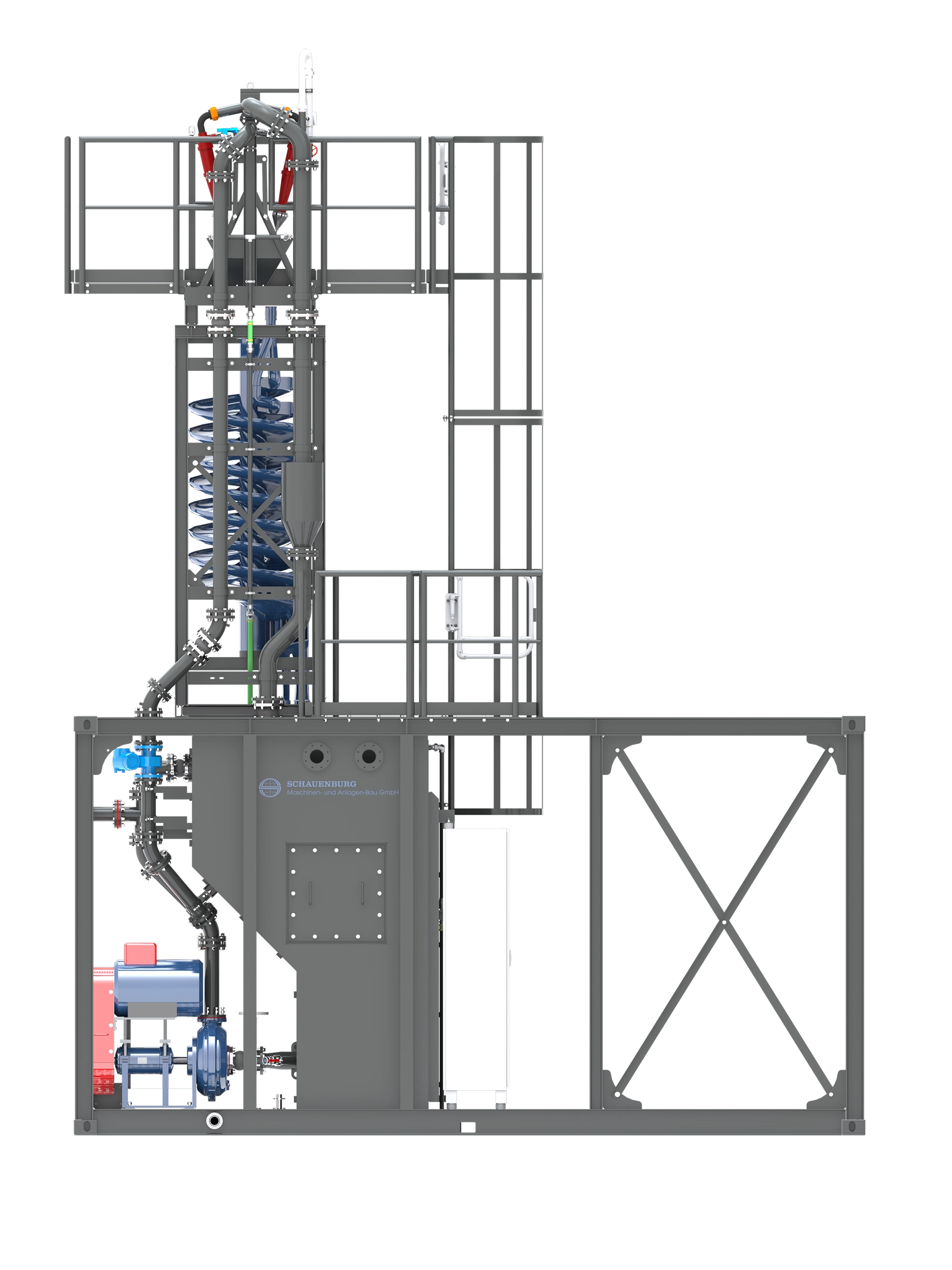

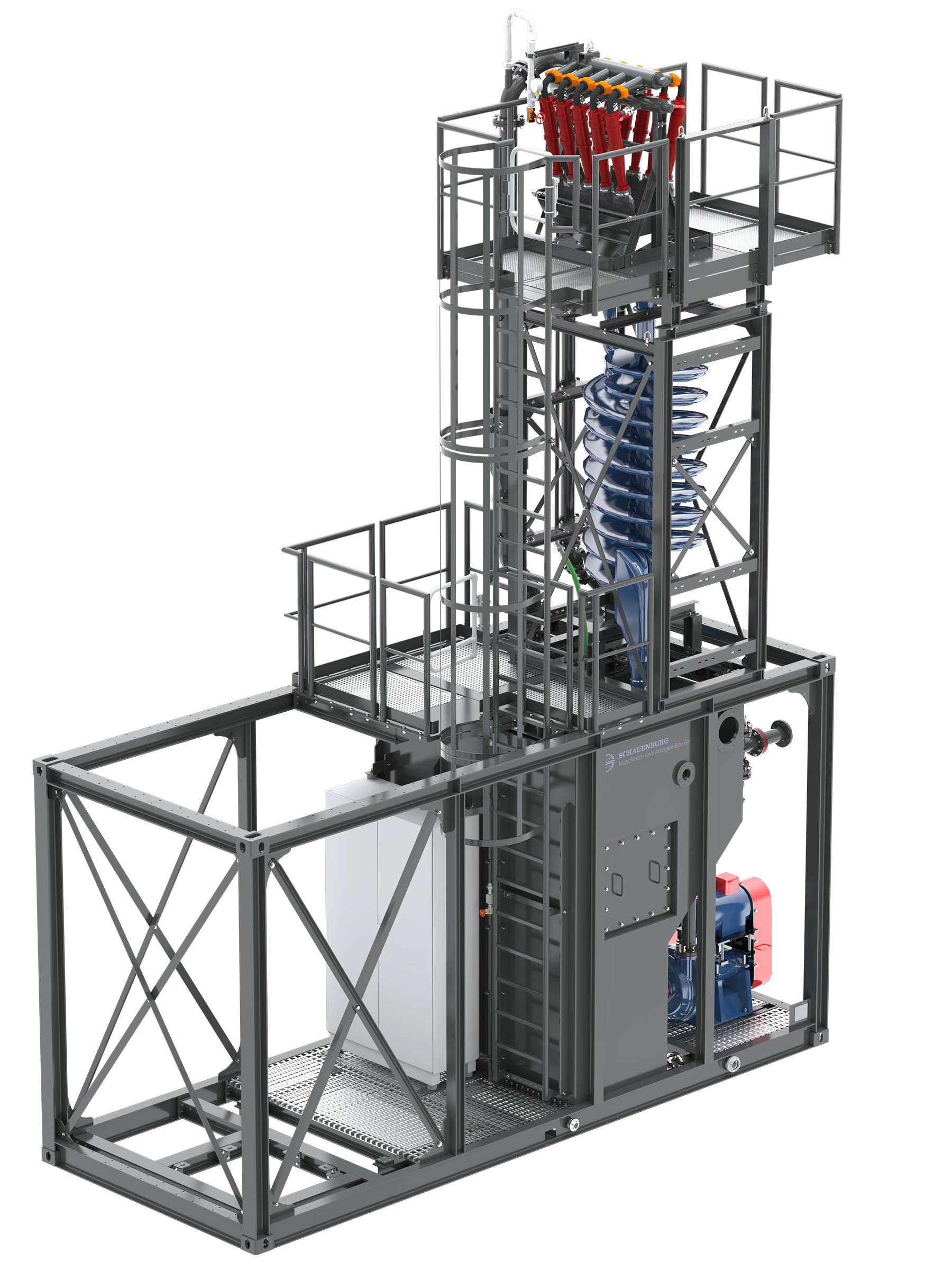

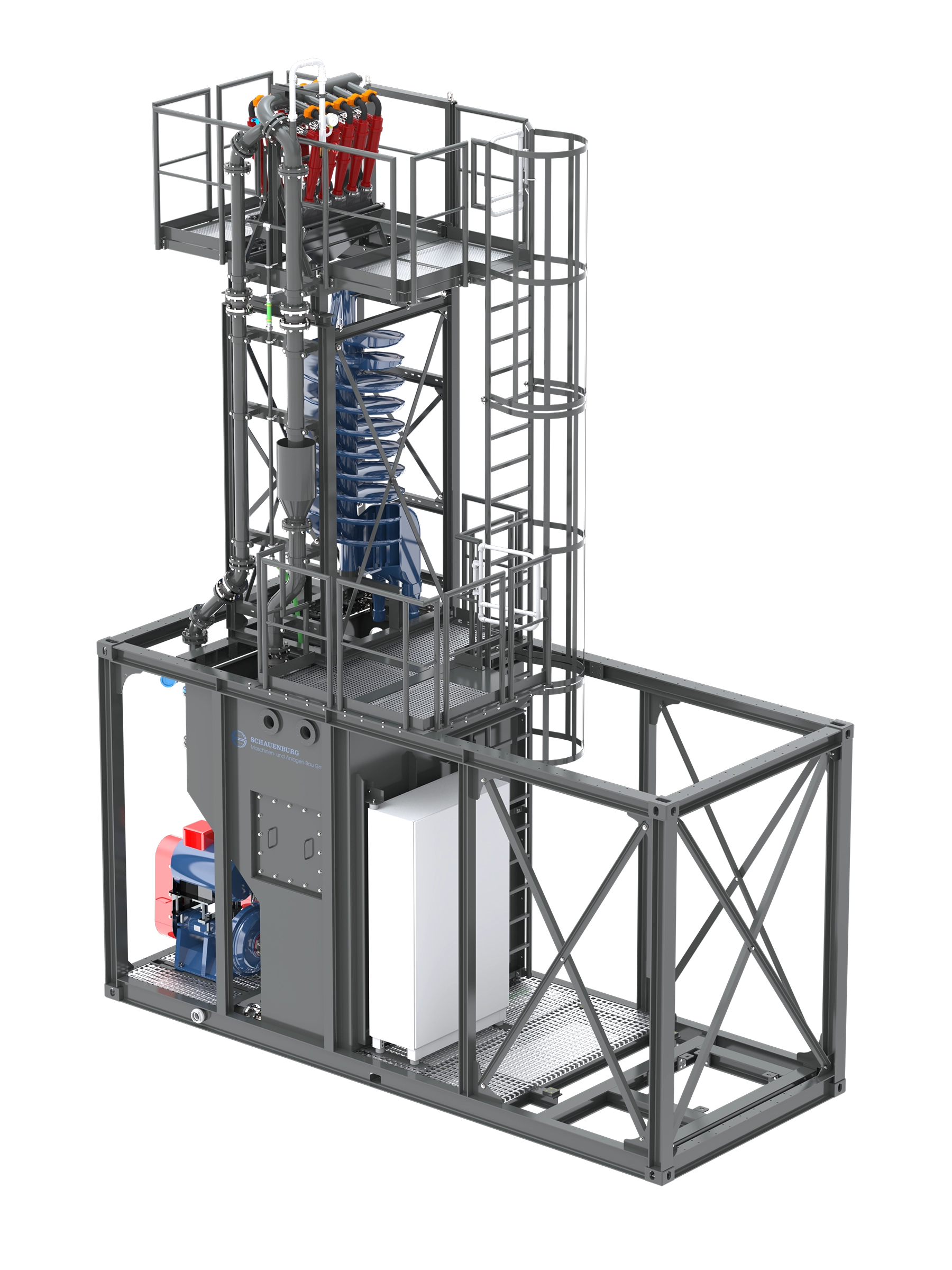

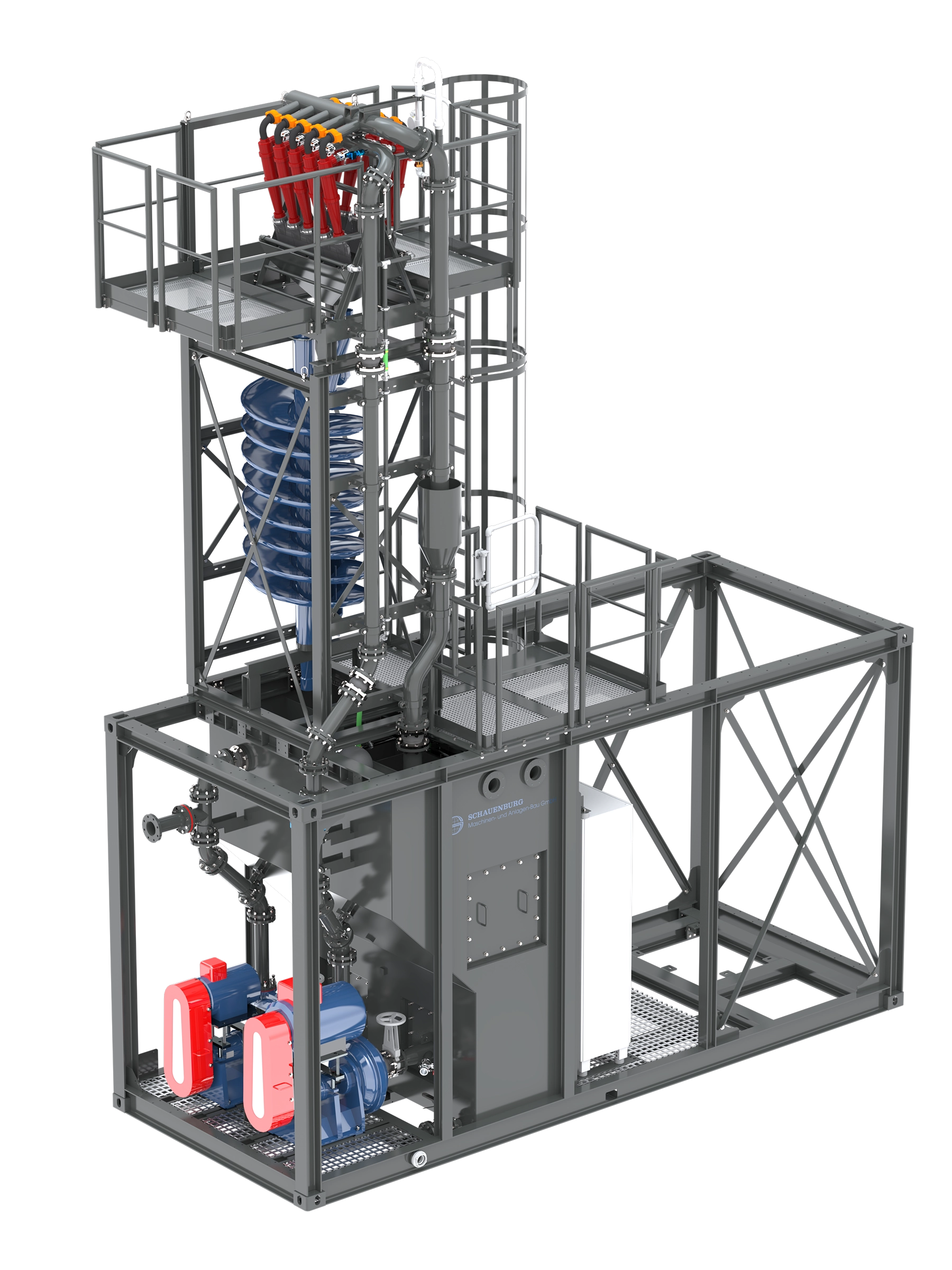

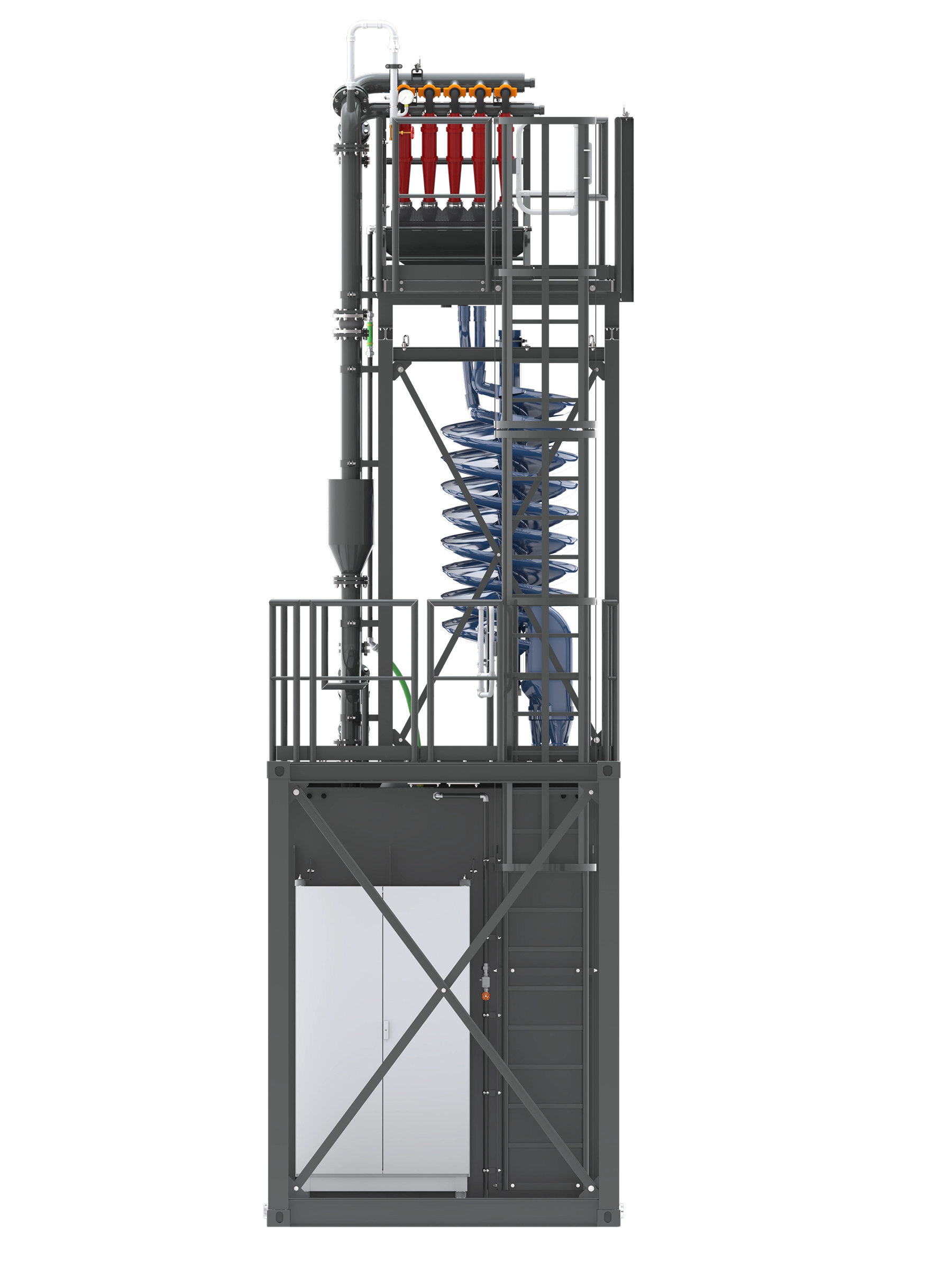

The Kudo is also a machine model and therefore particularly mobile. It consists of a pump, a pump feed tank, a spiral separator and has its own control unit.

The Kudo is mainly used for density separation in environmental and mining applications. Materials with different degrees of density can be easily separated with Kudo.

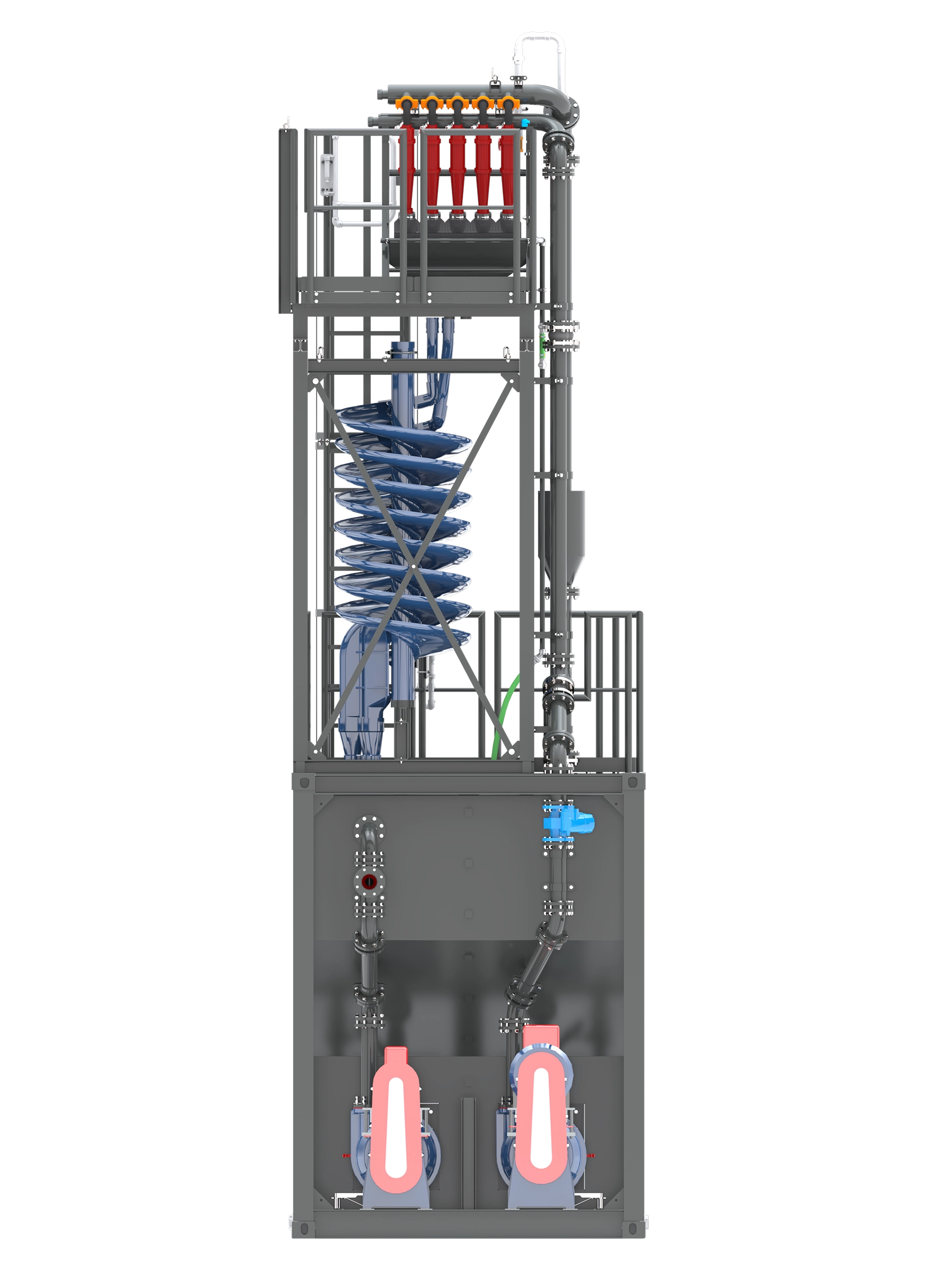

Spiral separators are used in many areas of the industry. Following the principle of centrifugal flow, light particles are carried outward while heavy particles remain inside and flow downward. The number of fractions, shape and inclination determine the result and are selected according to the task.

Specially adapted to our customers’ requirements, the Kudo was developed as a compact spiral separator unit for smaller applications and/or test work. It is characterized by its compact design, quick assembly and flexibility. Consisting of an underflow trough for receiving the incoming stream, a highly wear-resistant Linatex pump connected to it for feeding the multicycone, as well as another trough for the exception of the spiral discharge and a second Linatex pump connected to it for transfer to downstream processes. A combination and thus differentiated treatment of fine and medium material as well as heavy and medium material is possible.

The frequency-controlled Linatex pump in combination with cyclones that can be switched on or off makes a variable feed of 40-100m³/h possible. A combination of several units, different spiral separators covers a wide task field and high fluctuations in the feed:

Examples of applications:

- Mineral sand processing

- Iron ore processing

- Coal treatment