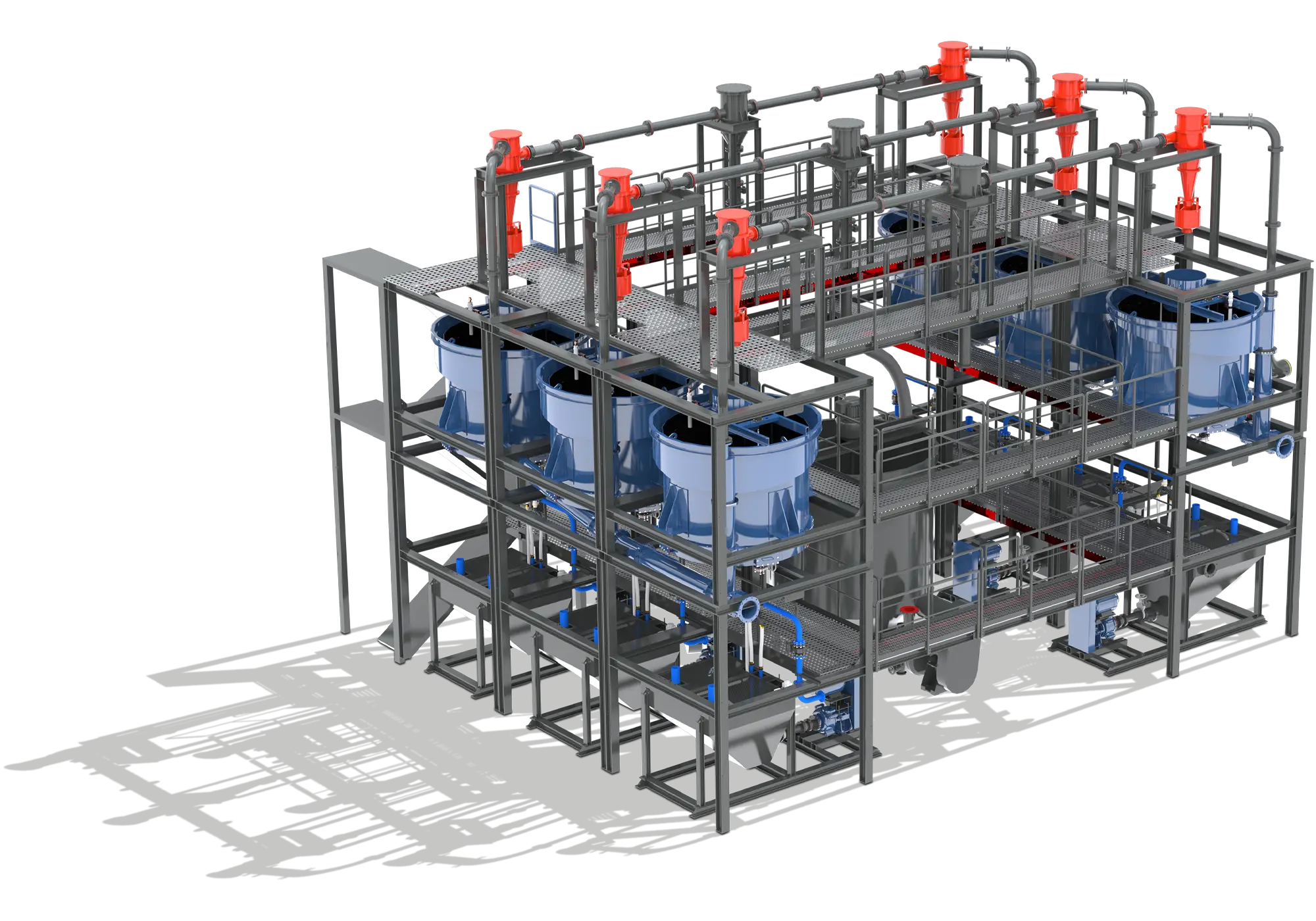

Sand, gravel, minerals and ores are valuable raw materials. In order to achieve an optimal utilization of the deposits, our plants are individually tailored to the respective conditions and requirements. Producers of sand, gravel, minerals and ores worldwide rely on Schauenburg MAB plants. They are characterized by very accurate end products, minimal material losses, low water and energy consumption, simple operation and low maintenance costs.

Our plants serve as a preliminary stage for ore processing. In a first step, the mined ores are washed, classified and sorted according to their specific weight. This leads to a significant reduction in operating costs in the subsequent process stages. In addition, fewer chemicals are required for further processing of the pre-treated raw materials.

Modern plants can no longer do without automated control. We offer our customers complete automation. In an intensive training, the operating personnel is familiarized with the control system. If desired, the plant can also be monitored and controlled by us online.

Our sorting equipment reliably removes light materials such as wood or coal from the raw material. This ensures the production of e.g. concrete, glass and quartz sand with high quality. Our components are retrofitted in numerous existing sand processing plants.